What is an ALD coating?

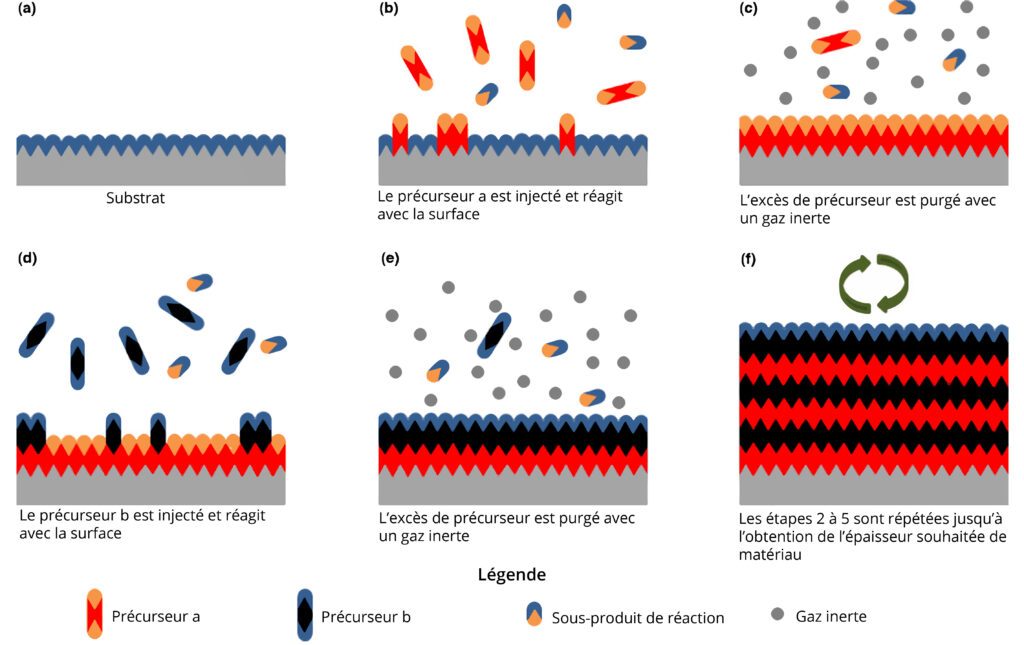

ALD is a deposition process which allows the deposition of thin films under vacuum thanks to gaseous pre-cursors.

The parts to be treated are placed in a vacuum machine.

After introduction of a pre-cursor A which deposit on all of the part’s surface, a pre-cursor B is introduced and reacts with the first atoms deposited to form the first atomic layer.

This cycle is repeated until the correct thickness is obtained.

Deposition temperature is between 150 and 200°C.

Application examples

Barrier properties

Excellent diffusion barrier properties

Application: Sensitive substrates

Constraints: Barrier layer

Solutions: ALD coatings

Identification

Intense color for better identification on steel, stainless steel, titanium, aluminum parts, etc.

Application: External fixators

Constraints: Biocompatibility, homogeneous color, mechanical resistance

Solutions: Colored ALD coatings

Biocompatibility

Application: Stents

Constraints: Barrier layer and 300% deformation on stainless steel parts

Solutions: ALD TiNO coating, …