Surcotec checks the degree of cleanliness of your parts by carrying out detailed surface assessments and can determine the type and the parameters of a chemical attack.

Example: Improve quality level, post-production inspection, final acceptance test, …

Surface assessment examples

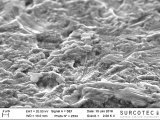

Surface modification

Inspection of surface condition, (after shot peening, sand blasting, …).

Titanium implants

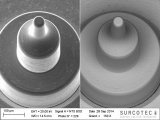

Machining

Observation of component finish looking for pollution and residual burrs.

Micrometric screw thread for medical application

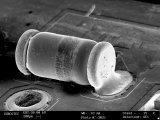

Production batch

Validation of a run of parts to avoid over high reject rate during assembly.

Watch gear elements

Conformity

Verification of manufacturing steps by rapid and pertinent visual inspection.

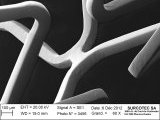

Stainless steel mesh under high resolution.