Surcotec can very precisely characterize your components in sensitive areas or problematic interfaces. Examples: pre-production inspection, R & D validation phase, customer claims, …

CHARACTERISATION EXAMPLES

Composition

Definition of the elements that make up the material on the surface or embedded.

20AP steel with sulphides and Pb

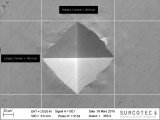

Hardness

Measurement of the hardness of an embedded or surface material with the possibility to obtain a profile.

Hardness footprint in 316 steel

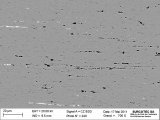

Inclusions / Impurities

Determine the spread (density and size) of elements within an alloy.

Sulphides in 20AP steel

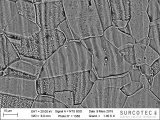

Microstructure

Analysis of the microstructure and determine the grain size.

Acid attack on gold to show the grain.

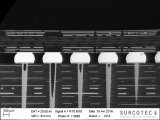

Metallic cross-section cuts

Composition and dimensional characterization of interface and crystalline makeup.

Sensor: intermetallic analysis after brazing

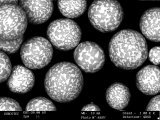

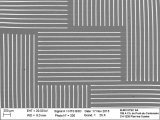

Alloys

Determine the different elements that make up an alloy.

Tin-lead solder beads.