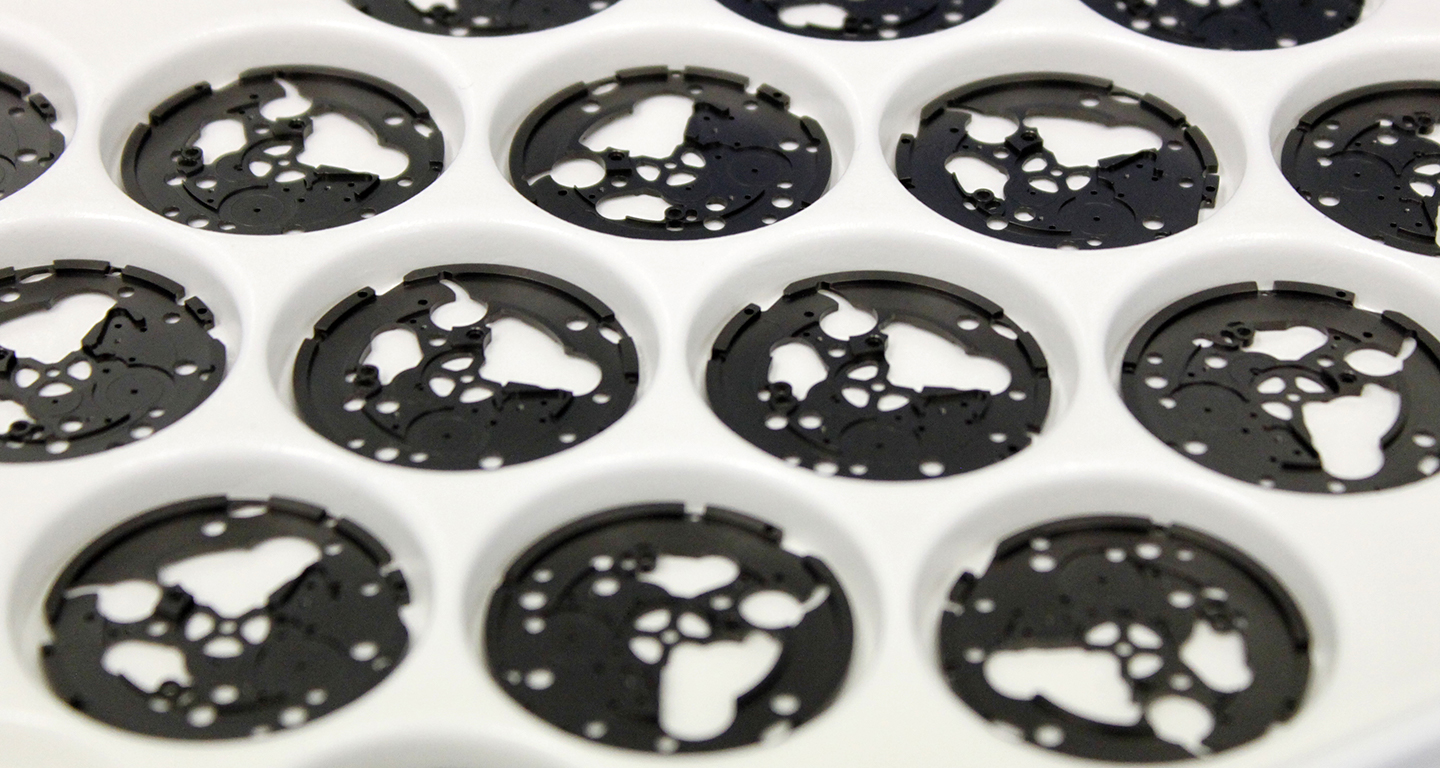

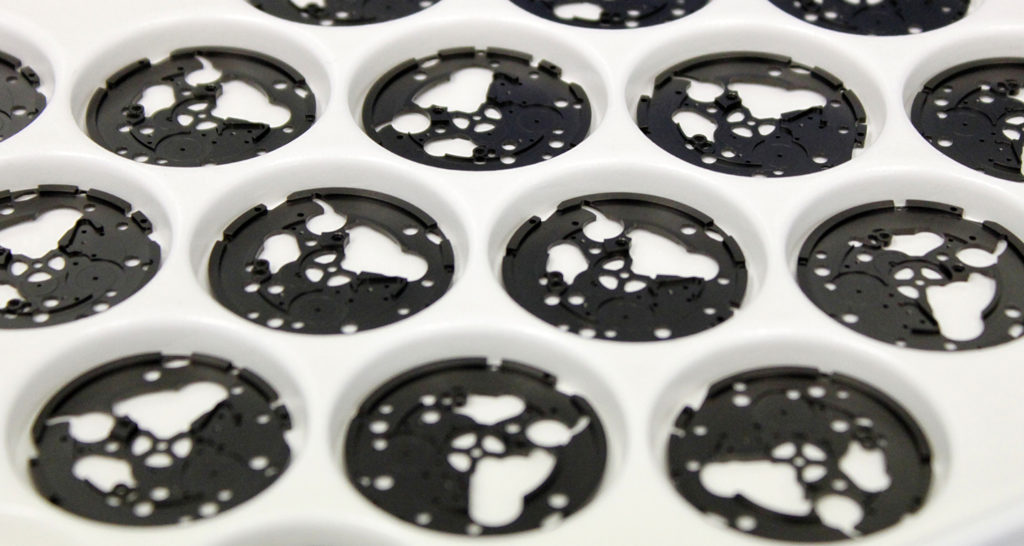

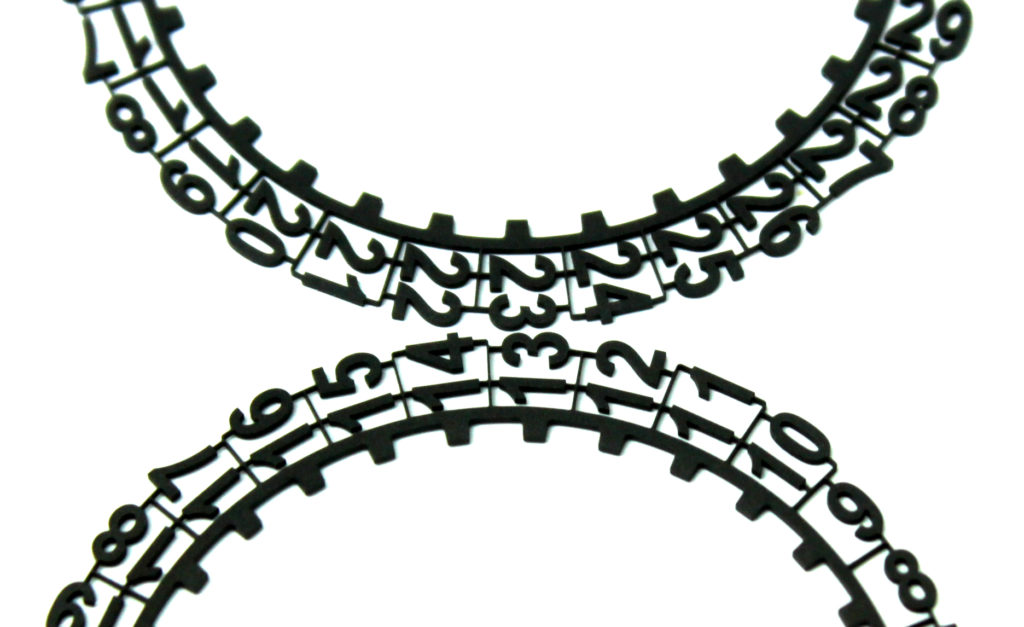

This black CM03 coating has been specially developed for the internal moving parts of watches that require a high resistance (date discs, barrel covers, etc.)

PHYSICAL VAPOR DEPOSITION (PVD) – PROCEDURE

PVD (Physical Vapor Deposition) is a metal deposition coating process that allows thin films of material to be deposited under vacuum using vapor.

For PVD coating the deposition temperature is usually between 80 and 150°C.

The deposit thickness is 2 +/-0.5 (micron)

HV 0.05 hardness is between 800 and 1000

Conforms to REACH and RoHS standards

Applications

Black CM03 colorized coatings

- Date discs

- Barrel covers

- Etc

The advantages

- Excellent quality for money

- Excellent results in watchmaking tests (climatic resistance, UV, etc.)

- Gloss, satin or matt black color depending on the substrate

- Black PVD can be deposited on all substrates (copper alloys, titanium, gold, steel and stainless steel, plastics)

- Clean deposit

- Good compromise between ductility and hardness

- Homogeneity and reproductivity of the color

- Homogeneity and reproductivity of thickness

- Resistance against climate and UV

- Low temperature procedure

- Respect of terminals

- A black PVD treated part can be detreated and retreated